Solar photovoltaic (pv) panel structure support system technology

Solar photovoltaic (pv) panel structure support system

The solar pv panel structure system is a special

bracket for the placement, installation and fixing of solar panels in solar

photovoltaic power generation systems. The general materials are aluminum

alloy, carbon steel and stainless steel.

Pile concrete solar PV ground structure solar panel system

The solar support system related products

are made of carbon steel and stainless steel. The surface of the carbon steel

is hot-dip galvanized. It will not rust for 30 years in outdoor use. The solar

photovoltaic support system features no soldering, no drilling, 100%

adjustable, and 100% reusable.

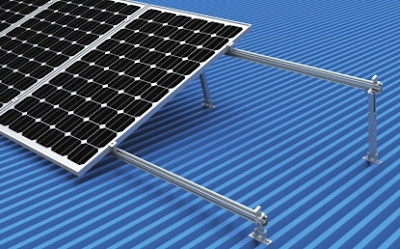

Roof mounting solar energy system

The world energy crisis has promoted the

rapid development of the new energy industry, and solar energy is the most

important basic energy source of all kinds of renewable energy; therefore, it

is a solar power generation technology that converts solar radiation energy

into electrical energy, that is, the photovoltaic industry is developing. In

the old concept, the photovoltaic industry mainly includes the production chain

of electrical control components such as solar module production chain, control

unit and inverter.

The advantages of solar support systems in

solar panel support go far beyond simple production and installation. Solar

panels can also move flexibly according to the sun's rays and the seasons. Just

as they were installed, the slope of each solar panel can be adjusted to

accommodate different angles of light by moving the fasteners, and the solar

panels are accurately held in place by retightening.

Material editing of solar photovoltaic

bracket

At present, solar photovoltaic supports

commonly used in China are divided into materials, mainly including concrete

supports, steel supports and aluminum alloy supports.

Concrete supports are mainly used in

large-scale photovoltaic power plants. Because they are self-important, they

can only be placed in the wild, and have better foundations, but they have high

stability and can support large-sized panels.

Aluminum alloy brackets are generally used

in solar energy applications for residential buildings. Aluminum alloys are

resistant to corrosion, light weight, beautiful and durable, but their

self-supporting capacity is low and cannot be applied to solar power projects.

In addition, the price of aluminum alloy is slightly higher than that of

hot-dip galvanized steel.

The steel bracket has stable performance,

mature manufacturing process, high bearing capacity and easy installation. It

is widely used in civil and industrial solar photovoltaic and solar power

stations. Among them, the steel is produced by the factory, with uniform

specifications, stable performance, excellent anti-corrosion performance and

beautiful appearance. It is worth mentioning that the combination steel bracket

system, its on-site installation, only need to use the specially designed

connecting parts to assemble the channel steel, the construction speed is fast,

no welding is needed, thus ensuring the integrity of the anti-corrosion layer.

The disadvantage of this kind of product is that the connecting parts are

complicated in process, various in variety, high in production and design, and

therefore expensive.

How to making so steel bracket?

Roll forming machine is very good optional production pv bracket c purlin.

PLC Control system, engineer just control the roll forming system by touch screen.

C type punch machine for punch hole, big production and high efficiciency.

Very good quality solar mounting roll former

回复删除Ya, many thanks.

删除Awsome steel profiles process machine

回复删除Can I book the bracket as per my design ?

回复删除Yes, sure, waiting for your detail.

删除How much this pv support 41mm c channel with hole punch forming machine

回复删除what is the bracket channel size, standard size ?

回复删除Very install this pv supports profiles.

回复删除